Item Category Generic items: Air fittings ASAs and drops Barrels Camera parts Detents Feednecks Marker parts: Autococker Automag DLX Luxe Eclipse Empire Mini classic Empire MiniGS Empire Axe classic Empire Axe Pro FEP Quest Impulse BLAST / Field One Shocker Sport Shocker SFT / NXT Shocker RSX / XLS Shocker CVO Tippmann X7 Tippmann Crossover TM7 / TM15 Vanquish

Information Tech support Dealers Warranty Contact About Nummech Reviews Development lab Legal Promo images

Development lab: Eclipse drop forward Eclipse markers have used their special T-slot mounting system all the way back to 2007, but somehow no manufacturers out there have taken the time to create any altered mounting systems such as drop forwards or drop backs. As with any marker, the use of a drop forward is purely a preference choice to the player, so even though drop forwards have gone "out of style" I would think there are still people that would like to have the choice for themselves.

As it turns out, there are people that want the choice. In early 2012, a couple individuals asked about the prospect of making a T-slot drop forward, in the same general shape as our Mini/Axe drops that we already make. Their only request was that the drop forward be slightly smaller in shape, which makes sense because our current Mini/Axe drop forward sizes were determined largely by the material necessary to mount the special bottomline regulator and the internal air passage. Eclipse markers aren't limited by the crazy pneumatics mounting system so the drop forward can be more traditional in shape.

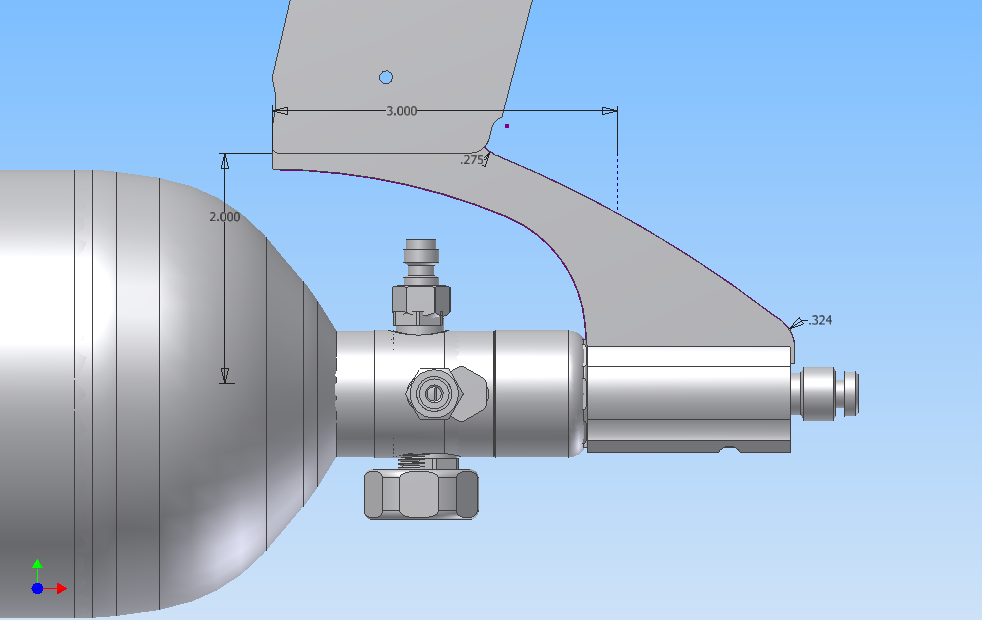

Early drop forward profile shapes (an Etek3 frame is pictured)

We eventualy narrowed down the specifications to something like the list below.

- Dimensions: 2" drop, 3" forward (approximate).

- Use the same angled cosmetic features as our Mini/Axe drop forwards.

- Similar teardrop milling as our Mini/Axe drop.

- Add one additional set screw for both the top and bottom mounting slots, for added stability.

- Compatibility with non-Eclipse frames (so the POPS item can be used with a non-T-slot marker) (if possible).

Our current Mini/Axe drop forwards are machined using a set of special fixturing clamps that were made to function with the unique shape of the workpiece. Any drop forwards that we make which share a similar side profile can also be made to use the same fixtures, which would save quite a bit of time and money. (less cost for us means less cost to the players!)

Additionally, using similar styling queues from the Mini/Axe cosmetic features, would easily help even more. In theory the drop forward could be accented with complex 3d contours however these would take much more time to machine, and would increase the cost as a result.

A functional T-slot drop forward, before teardrops.

The cosmetic featues being slightly similar from one drop forward to another may not seem like a consequential detail, but it's actually quite noticeable in terms of the time and money that goes into the production side. The customized fixturing I mentioned earlier took several hours to create (not to mention the cost of the raw materials) so being able to re-use the same parts for another product is very useful. I wanted to make light on this issue since similar situations can be seen in some other paintball items as they change and evolve from version to version. The smaller the change, the less money was required for it.

Prototypes Once the prototyping was complete, we had two initial parts ready for use (pictured below). They are very close to the original design with the small exception of a few slight alterations where the machining process had to change. When an actual production batch is made, those items will be exactly as the CAD models show above.

Drop forward prototypes, before and after anodizing.

As always, the prototype items are rough looking and not quite as refined when compared to the pretty CAD images. While making the prototypes, the exact parameters of the machining program are adjusted and refined to the point where a presentable item can be created. Our machinists are very experienced with it, which allows them to predict the changes needed to fix any little quirks in the production process for when the final product needs to be available.

Both of the testing players requested a dust finish to match their current markers, so the prototypes were blasted with glass beads to produce a matte finish similar to the factory "dust" anodizing. It's likely that any additional drop forwards for Eclipse markers will also be done in blasted finish, since they can match the vast majority of Eclipse's factory anodizing.

Production models We plan to manufacture a batch of these and make them available to other players in the near future. At the moment finding machine time is difficult but rest assured these drops will definitely be available soon.

Update: These drop forwards are now available!